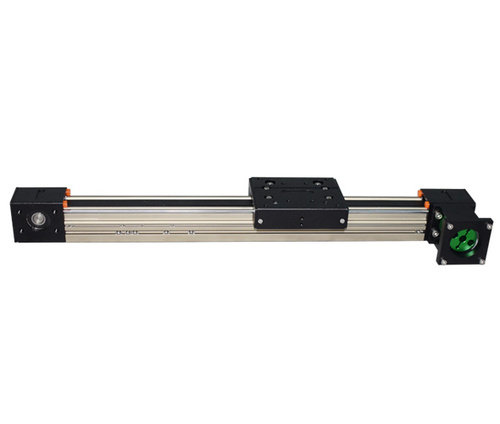

The linear module is a set of equipment that is widely used in modern automation parts. Its names are also varied. Some are called linear modules, some are called electric cylinders, some are called slides, and some are called robotic arms. Although they are called The methods are different but their working principles are the same.

Linear module work case

It can be divided into synchronous belt drive and ball screw drive, but their working principles are the same. The linear module is a modular product designed to integrate the servo motor, screw and synchronous belt, converting the rotational motion of the servo motor into Linear motion, while transforming the best advantages of servo motors - precise speed control, precise revolution control, precise torque control into - precise speed control, precise position control, precise thrust control; to achieve high-precision linear motion, the following is a detailed introduction to synchronous belts and How ball screws work.

Synchronous belt linear module

1.Working principle of synchronous belt linear module

The synchronous belt linear module is mainly composed of belts, linear guide rails, aluminum alloy profiles, couplings, motors, photoelectric switches, etc. The belt is installed on the drive shaft on both sides of the linear module, and the power input shaft is fixed on the belt to block the slider of the device. When input is used, the slider is driven by a belt. Usually the belt linear module has been specifically designed so that the tightness of the belt can be controlled on one side, which facilitates the debugging of the equipment during the production process. Synchronous belt linear modules can use rigid rails according to different loads to improve the rigidity of the linear module. Linear modules of different specifications have different load upper limits. The accuracy of timing belt linear modules depends on the combination of belt quality and machining process. Control of power input affects belt accuracy.

Ball screw linear module

2. Working principle of ball screw linear module

It is mainly composed of ball screw, linear guide rail, aluminum alloy, ball screw pair, coupling, motor, photoelectric switch, etc. Ball screws are ideal products for converting rotary motion into linear motion or converting linear motion into rotary motion. Ball screws consist of screws, nuts and balls. It converts the function of rotary motion into linear motion. This is the further promotion and development of the ball screw. The important significance of its development is to transform the bearing from rolling motion to sliding motion. Ball screws are widely used in various industrial equipment and precision instruments due to their small friction resistance. High-precision linear motion can be achieved under high load conditions.

These are the working principles of linear modules. Although it is very simple to say, the most important thing is high precision. This is also the biggest technical problem of domestic linear modules. In Germany, Japan, South Korea, etc., their production of linear modules The accuracy of the assembly is very high, so when choosing a product, you still have to match it according to the machinery of your own factory.