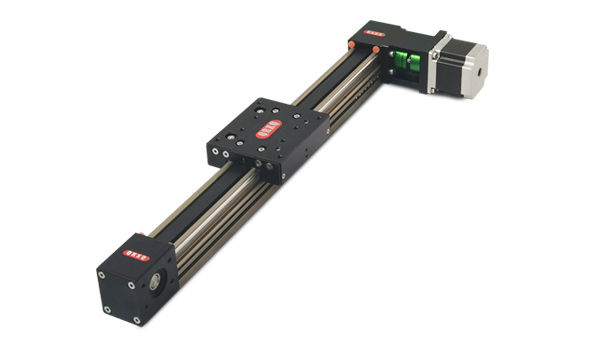

Linear module, also called linear module, is a motion unit that modularizes a linear motion platform. It precisely assembles the guide rail system and transmission system into one unit. This kind of system integration greatly facilitates the design and selection work of engineers and makes the assembly of equipment simple and modular. Common mechanical transmission systems on the market include the following: screws, synchronous belts, and racks and pinions; the driving of these transmission systems is achieved by rotating motors/reducers; these mechanical transmission systems, due to the relatively long transmission chain, the system accumulates Due to errors and other reasons, the transmission accuracy and response speed cannot meet the requirements of certain applications.

If a linear motor is used to achieve direct drive, it eliminates the need for intermediate links in the transmission chain such as reducers, screws/belts/racks and pinions, and improves the transmission accuracy and response speed of the system; linear modules integrating linear motors, Known as linear motor module or linear motor slide:

The application of linear motors in industrial equipment is mainly due to the convenience of machine tools. In recent years, the use of linear motors in CNC machine tools has become particularly popular internationally. The reason is that the driving device of traditional machine tools is screw drive, and the screw drive itself It has: length limitation, mechanical clearance, accuracy problems after friction, etc., while linear motors can achieve ultra-high accuracy, with speeds that are 10 times or more that of lead screws.

Today, with the rapid development of science and technology, linear motor technology can achieve high precision, almost zero maintenance, and no backlash in the continuous improvement of linear motor technology. It meets human needs and improves human good wishes while also seeking its own development in the future. The prospects are bright.

Linear motors are different from traditional transmission methods

• High stiffness, no transmission backlash and flexibility

• Wide speed range (1um/s—5m/s, lead screw <1m/s)

• High dynamic performance and high acceleration, up to 10g

• Extremely high motion resolution and positioning accuracy

• Unlimited trips

• No wear and maintenance

• Integrated mechanical system design and easy adjustment